Digital calipers are precision measuring instruments used for determining the dimensions of an object by gauging the distance between two opposing sides. They are favored for their accuracy, ease of use, and versatility in various industries, including manufacturing, engineering, and electronics. The emergence of digital calipers has revolutionized the way measurements are taken, offering features like an easy-to-read LCD display and the ability to seamlessly switch between metric and imperial units.

The underlying technology behind digital calipers relies on a series of capacitance sensors, an engraved copper pattern, and a movable slide with embedded circuitry. The stator, or stationary part, houses an array of plates that create the capacitive array used to detect motion. The slider, or the movable part, has a complementary circuitry featuring thin strips of conductive material that resembles a comb. As the slider moves, the interaction of these elements generates an electric signal that corresponds to the distance measured.

In essence, digital calipers provide a significant advantage over their traditional counterparts, such as dial or Vernier calipers, in terms of efficiency, accuracy, and convenience. Through rapid advancements in electronic components and sensors, industries now have access to more reliable tools for intricate and critical measurements, ensuring greater consistency and precision in their work.

Digital Caliper Components

Digital calipers are precision instruments used for measuring various dimensions with high accuracy. This section will discuss the main components of set of Mitutoyo digital calipers, focusing on the following sub-sections:

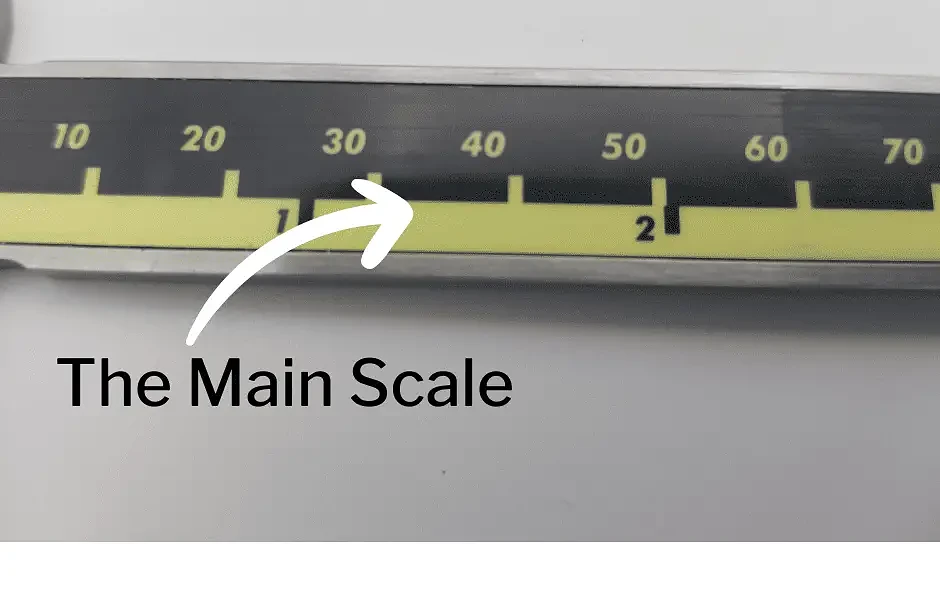

Main Scale

The main scale is the part of the caliper that features engraved markings representing increments of measurement. In digital calipers, it often serves as a reference for the electronic measuring system. The main scale typically displays measurements in inches or millimeters, with a resolution of 10 µm.

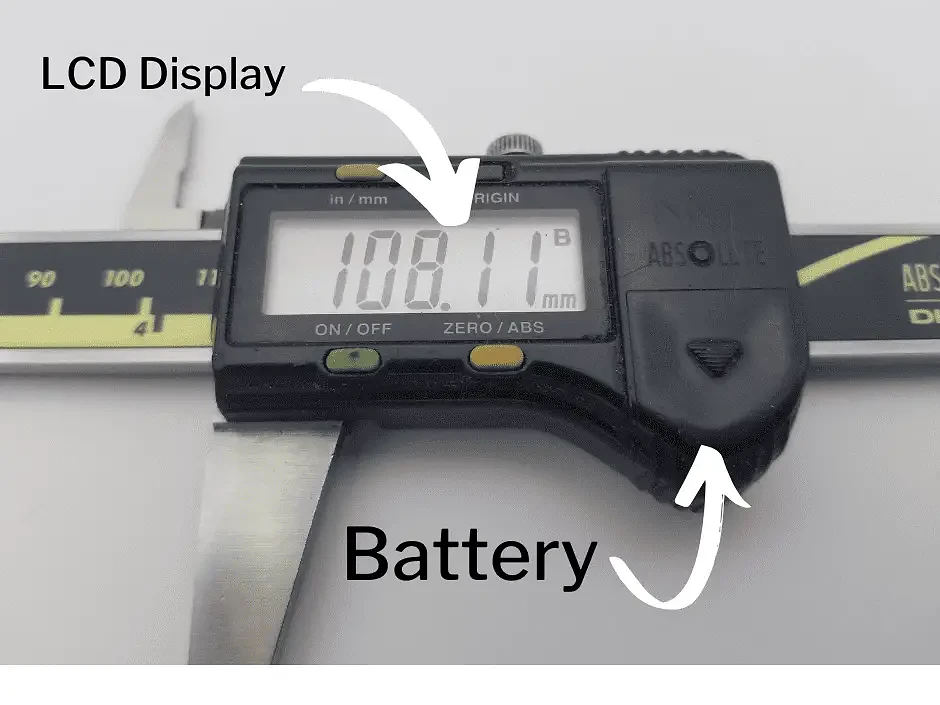

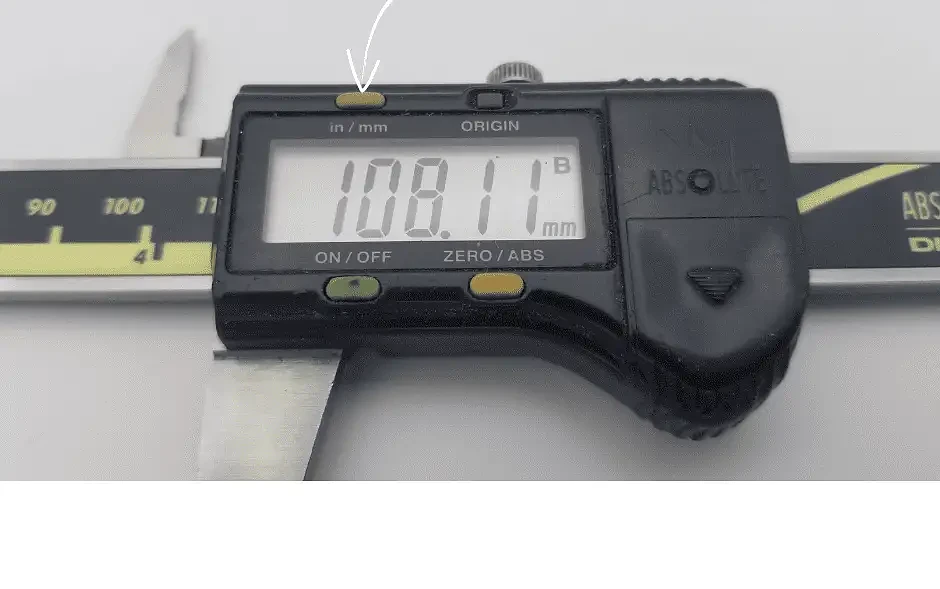

LCD Display

Digital calipers feature an LCD display that provides a clear, easy-to-read output of the measurement taken. This display eliminates the need to manually interpret the calibrated scales commonly found in Vernier and dial calipers. The LCD display enables users to quickly and accurately read measurements without ambiguity.

Slider

The slider is a movable component on the caliper that allows the user to adjust the measurement jaws. It is connected to the electronics system and moves along the main scale, working in tandem with the digital capacitive array to detect motion and provide accurate readings.

Electronics

A crucial component of digital calipers is the electronics system, which primarily consists of a capacitive array. The capacitive array is composed of many plates and detects motion by measuring changes in capacitance between plates as the slider moves. This system allows the digital caliper to provide precise and reliable measurements.

Battery and Power Source

Digital calipers require a power source, typically a small battery, to operate the LCD display and electronics system. This battery ensures consistent, uninterrupted performance and precision while measuring. Battery life varies between models but often lasts a significant amount of time before needing replacement.

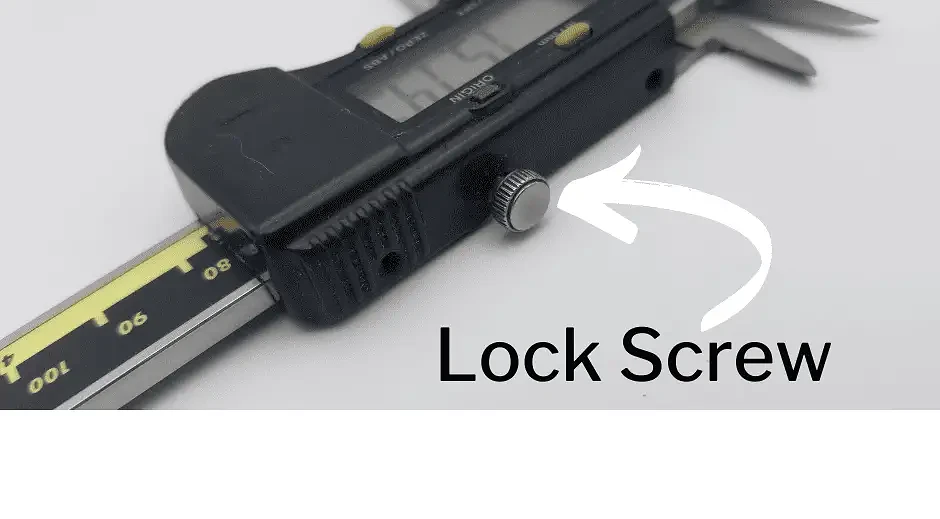

Lock Screw

A lock screw is a practical feature included in some digital calipers to keep the jaws in a fixed position during measurements. By securely holding the slider in place, the lock screw helps maintain accurate positioning and prevents accidental adjustments that could affect measurement accuracy.

How Digital Calipers Work

Capacitive Sensors

Digital calipers, also known as electronic calipers, use capacitive sensors to detect motion and provide precise measurements. These sensors consist of a capacitive array constructed from many plates, including the stator and slider (or “rotor”). The electrical enclosure that houses these capacitive components is held in place by a metallic ruler into which the stator is fitted, while the electrical housing incorporates the slider.

Reading Measurements

To take measurements with a digital caliper, the user opens the jaws and places the object between them. There is usually a thumbscrew on the device to close the jaws gently until both jaws are in contact with the object. The measurement is then displayed on the digital screen. Digital calipers can measure the inside and outside dimensions of objects, as well as the depth, step, or height, using the internal and external measuring jaws and the depth rod.

Metric and Imperial Conversion

One of the key advantages of a digital caliper is the ability to easily convert measurements between metric and imperial units. Digital calipers often have buttons that enable users to switch between inches and millimeters, allowing for seamless conversion and easing the process of dealing with mixed-unit measurements, commonly encountered in electronics and other industries.

Accurate Measurement

Digital calipers are known for their high degree of accuracy, with typical accuracy levels of 30 to 40 µm and a resolution of 10 µm. This level of precision allows for consistently reliable measurements in various applications, making digital calipers an indispensable tool in many fields.

Caring for and Maintaining Digital Calipers

Cleaning and Protecting

Taking care of digital calipers involves regularly cleaning and protecting them from dirt and debris. These instruments are often used in construction sites, carpentry workshops, and other professional settings where impurities can easily accumulate. To clean your digital caliper, gently wipe its measuring faces with a soft, clean, and lint-free cloth. Avoid getting the caliper wet, as moisture can damage its electronic components.

Recalibration

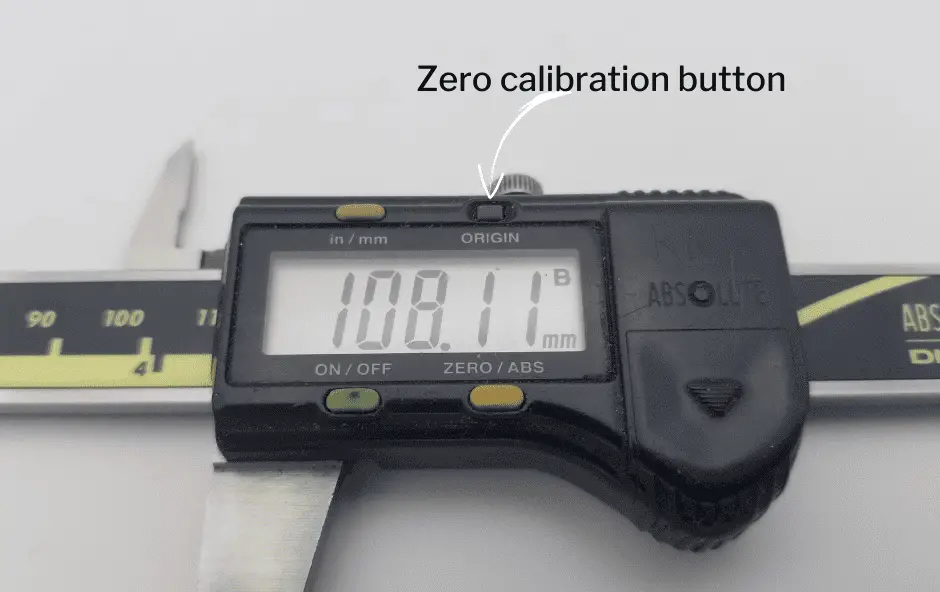

Before using a digital caliper, recalibrate it by pressing the zero button. This eliminates any discrepancies from previous measurements. Close the jaws gently and check that the display reads zero; if not, press the zero button again to reset. If the instrument doesn’t consistently show a zero reading, this may indicate a dirty or fouled rack, in which case you should clean the caliper and check again.

Battery Replacement

Another crucial aspect of maintaining digital calipers is battery replacement. A weak or dead battery can result in inaccurate measurements or a non-responsive instrument. It is important to replace the battery as soon as you notice signs of weakness, such as erratic readings or a flickering display. Make sure to turn off the caliper and remove the old battery carefully, placing the new battery in its designated compartment with the correct orientation.

By keeping your digital caliper clean, dry, and properly calibrated, you can ensure its accuracy and longevity in your toolbox.

Factors to Consider When Purchasing Digital Calipers

When looking to purchase digital calipers, there are several essential factors to consider, including accuracy, materials and build quality, price, and brand.

Accuracy

Accuracy is a vital factor when selecting a digital caliper. Digital calipers are typically highly accurate, with some offering a resolution of 10 µm and an accuracy of 30 to 40 µm. To ensure accurate measurements, calipers must be kept clean and well-maintained.

Materials and Build Quality

Digital calipers come in various materials, each with its own pros and cons:

- Stainless steel: This is a popular choice due to its durability, rust-resistance, and good accuracy. Stainless steel calipers are reliable and long-lasting, requiring minimal maintenance.

- Plastic: Digital calipers made from plastic may be less expensive, but they can’t offer the same durability and accuracy as stainless steel devices. Plastic is more prone to wear, warping, and breakage.

When evaluating build quality, also consider factors such as:

- Smoothness of the caliper’s sliding motion

- Quality of the electronic components

Price and Brand

Price is another important aspect to consider when purchasing a digital caliper. While it’s not necessary to choose the most expensive option, be cautious of extremely low-priced calipers, as they may lack accuracy and durability. Trusted brands with positive reviews can provide greater assurance of product quality. As an Amazon Associate, it is possible to find a wide range of digital calipers from various reputable brands at different price points, making it easier to choose one that suits your needs and budget.