There are dozens of different dial indicators on the market, in this review I will explain what I consider to be the best dial indicator for a cnc hobbyist.

Product Reviews

All industrial supply dial indicator

Clockwise tools digital dial indicator

HFS(R) 0-2″ Precision Travel Dial Indicator

Anytime Tools Extension Stem Rod Set

What is a dial indicator?

A dial indicator is a measuring instrument that amplifies a distance so that it can be read on the ‘face’ of the indicator.

The face of the indicator resembles a clock face with two arms that give large and smaller increments of the distance the plunger travels.

You read both the large dial face and the smaller inset dial face to read the total distance the plunger travelled. The larger dial face gives the reading of the smallest increments.

What are the different types of dial indicator?

The two most common types of indicator are the dial indicator (as shown above) and the dial test indicator also known as the finger dial.

Test Indicators differ from dial indicators by having a lever arm instead of a plunger.

The arm pivots back and forth about a hinge point and can measure in both directions.

This arm can be positioned where you need it, just carefully push the arm to the to overcome the friction that holds it in place.

Test indicators have less movement than plunger dials and are physically smaller as well.

What is a dial indicator used for?

When dial indicators are used for machining their main function is to check that a workpiece is running parallel to the axis of movement. Also to confirm if a rotating part is running true to the center of rotation when used in a lathe or rotating axis on a mill.

They do have many other uses however, such as measuring sizes. The plunge style would be the best type of dial indicator for an inspection department where they can be used to quickly measure a large batch of identical parts.

Readout on manual micro lathe

I have a dial indicator with 2” of travel setup on my Taig Lathe as a readout. It allows me to accurately travel an exact distance in the Z axis. The plunger on the dial is set against the carriage on the lathe.

Engine building

Dial indicators are used in engine rebuilds or for maintenance. When mounted on a magnetic stand they can be used for finding top dead center of a piston or measuring the amount of lateral movement or ‘play’ in a crankshaft.

How to use a Dial indicator

Among the most common dial test indicator use for a machinist is clamping them in the spindle.

Mounting them on an arm in the spindle enables the Z column to be swept to ensure it is perpendicular to the table.

Using a finger dial in the spindle also lets you pick up the center of a part to set your X and Y axis datums and to dial the center of a hole.

Dialing the center of a hole is done by positioning the dial in the hole so the dial arm is contacting the circumference. Then rotate the spindle by hand and adjust the X and Y axes until the readout stays on zero all around the circumference of the hole.

The machine will now be positioned on the center of the hole.

How do You set them up?

I usually mount my small finger dial in the spindle to square up the vice on my taig mill or alternatively a small magnetic base can be used to hold it against the Z axis column.

Test indicators are smaller than a standard dial indicator, making them perfect for use in a small benchtop cnc milling machine.

How do they work?

A basic dial indicator works using a rack and pinion system. The plunger has teeth ground into one side which rotates a series of gear wheels, which in turn rotate the arms on the dial.

The plunger is also spring loaded to make it return to its fully extended position and keep the tip in contact with the surface being measured.

Product Reviews

I have reviewed 5 of the best dial indictors available online for you to choose from.

Khcraft dial test indicator

This is a small dial indicator and is identical to the one I bought for my Taig cnc mill. The build quality and supplied attachments are not as good as a mitutoyo or starrett but I have not had any issues with it and it does the job. It is also more compact than the more expensive dials making it ideal for a small mill.

- Range: 0-0.03" graduation: 0.0005"

- Made of steel hardened with all metal components, durable satin chrome finish

- with 2 Steel Dovetail Clamps 3/8'' and 5/32'', dovetail mount on top and back and front for all-around positioning, 2 ways to fix on the magnetic base: stem (3/8" or 5/32") or dovetail (top or back or front)

- All finished dial test indicators are inspected 100% piece by piece to control the accuracy

All industrial supply dial indicator

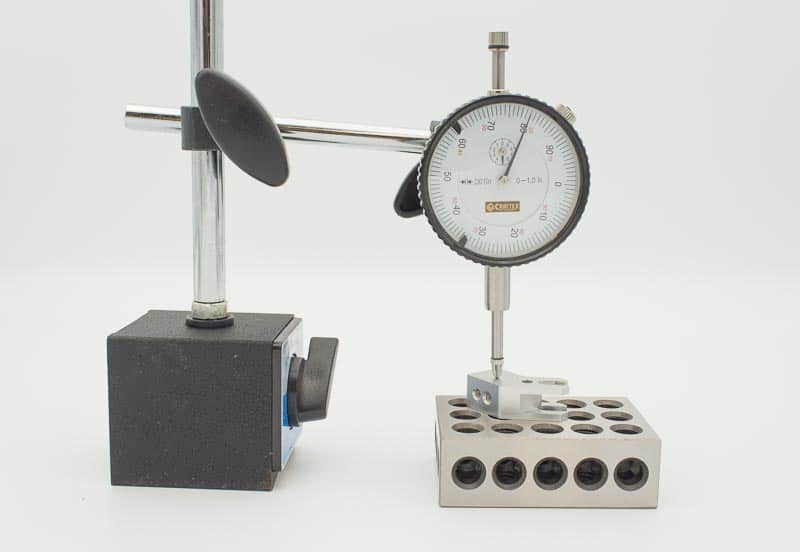

This is a typical generic dial indicator and magnetic stand. Similar to the one I own. (I am pretty sure they all come from the same factory). It will do what you need and will last a long time if you look after it. Even if it does get damaged the dials can be bought individually and are really inexpensive.

This set includes a box of interchangeable heads. The thin ones are really useful although I am not to sure what the bent one can be used for….

- 3 Piece precision inspection set includes: 0-1" .001" dial indicator, magnetic base and 22 piece. indicator point set. Complete with hard plastic case

- 1" dial indicator: graduation 0.001", 3/8" stem diameter, 2" dial face and lug back

- Magnetic base: overall height 9", on and off switch, 130 lb. power pull, base measures 2" width X 2-1/2" depth

- 22 pc. indicator point set: AGD specifications (4-48 threads)

Clockwise tools digital dial indicator

Just like micrometers and calipers there are digital versions available. The main advantage is the ability to switch between metric and imperial measurements. I don’t own one of these so if you want one, check out the reviews on Amazon before you buy. I prefer the reliability of an analogue gauge.

- Dual Unit Conversion & Large Display – Supports both inch and metric readings, with a 1.6" x 0.7" LCD screen for clear, precise measurements. Auto-off after 5-7 minutes, retains zero position when turned on again.

- High Precision & Accuracy – Features a 0-1" (25.4mm) measuring range, 0.0005" (0.01mm) resolution, and ±0.001" (0.03mm) accuracy, ensuring reliability for fine measurements in machining and inspection tasks.

- Strong Magnetic Base for Stability – Equipped with two magnetic faces and a maximum pull of 176 lbs (works best on 30mm+ thick metal/steel). Thinner metal surfaces may reduce magnetic force.

- Versatile Mounting & Compatibility – Comes with flat back and lug back options (hole size 6.5mm), a 3/8" stem diameter, and a UNF 4-48 threaded tip, allowing secure attachment to various setups.

- RS232 Data Transfer for PC Connectivity – Designed with an RS232 port for seamless data transfer. Requires “Clockwise Tools DTCR-01” cable (sold separately, NOT USB compatible).

Mitutoyo dial test indicator

I use this dial test indicator at work, it is pretty much the gold standard for test indicators. If you want the best, this is what you have to buy.

- Contact point effective length is printed on the dial face

- Increased impact resistance and durability of gears and bezel

- Inspection certificate included with bidirectional evaluation

- Increased scratch-resistance of crystal

HFS(R) 0-2″ Precision Travel Dial Indicator

This is the Dial Indicator I bought for my Taig Lathe. I choose this one specifically for the 2” travel as opposed to the typical 1” travel on most indicators. It is reasonably priced and works perfectly as an analogue readout on my micro lathe.

I made an aluminum stand off to mount it to a small dia bar which I was using as a stop to prevent the carriage from hitting the chuck. I can now set the stop and then slide the dial along it to position it where needed.

- [Size]: Measuring Range: 0 - 2"; Accuracy (1st 2.5 Rev): +/- 0.001", Accuracy (Overall): +/- 0.003"; Reading: 0-100; Lug Back: 1/4" Holes; Dial Diameter: 2.28"; Stem Diameter: 3/8".

- [Durable Construction]: The dial indicator features an aluminum body, jeweled bearing, and a revolution counter with a dial lock screw.

- [AGD2 Standard]: Compliant with AGD2 standards ensuring reliability and consistency.

- [Enhanced Visibility]: Easy-to-read aluminum dial face with an anti-glare finish and a 2.28" dial diameter for clear readings.

- [Versatile Mounting]: Equipped with a lug back with 1/4" holes and a 3/8" stem diameter for flexible mounting options.

Anytime Tools Extension Stem Rod Set

I had to add these to my recommended list. They are perfect for a setup similar to my lathe where I am using a dial indicator as a readout. Just add or remove the extensions to the dial to position it on the Z axis. This enables me to move the ‘readout’ to measure the carriage movement where It is needed.

- Includes 6 pieces in lengths 1", 2", 3", 4", 5", 6". Make any combination up to a total of 21".

- Easy positioning, tight hold.

- 4-48 standard indicator tip thread