Metals are an essential part of our daily lives, with numerous applications in various industries. They come in a wide variety of types, each with its own unique properties and uses. Understanding the different types of metals and their applications is important for engineers, manufacturers, and consumers alike, as it helps them make informed decisions when selecting materials for specific purposes.

One of the most commonly used metals is steel, which is an alloy of iron and carbon. Steel can be further classified into various types such as carbon steel, alloy steel, and stainless steel, with each type having specific applications and properties. For example, stainless steel is known for its corrosion resistance, making it ideal for use in kitchen appliances and engineering projects where durability is crucial.

Another important category of metals is non-ferrous metals, which do not contain significant amounts of iron. Some examples of non-ferrous metals include aluminum, magnesium, and tungsten. These metals offer unique advantages like being lightweight, high-strength, or high-temperature resistant, making them suitable for a range of applications. Therefore, getting familiar with the characteristics and uses of different metals is essential for those involved in manufacturing, construction, and other industries that rely on these versatile materials.

Main Types of Metals

Steel

Steel is an alloy primarily composed of iron and carbon. It can be classified into three main types: carbon steel, alloy steel, and stainless steel. Carbon steel is made solely of carbon and iron – the higher the percentage of carbon, the stronger and more expensive the steel becomes.

Alloy steel contains other elements like chromium, nickel, and manganese, which add specific properties to the material, making it ideal for automotive and construction industries. Stainless steel is resistant to corrosion due to the presence of chromium, making it suitable for various applications, such as kitchen utensils and medical equipment.

Iron

Iron is a widely used metal and an essential component of steel production. There are two main forms of iron: wrought iron and cast iron. Wrought iron has a relatively low carbon content and is ductile, making it suitable for ornamental work, gates, and fences. Cast iron, on the other hand, has a higher carbon content and is more brittle – it’s commonly used in engine blocks, pipes, and machinery components.

Aluminum

Aluminum is a lightweight and versatile metal. It has high corrosion resistance, excellent thermal conductivity, and good electrical conductivity. Aluminum is widely used in aerospace, automotive, and packaging industries, thanks to its low density and ability to be easily formed into various shapes. It is also a popular metal for electronic devices, construction materials, and consumer goods.

Copper

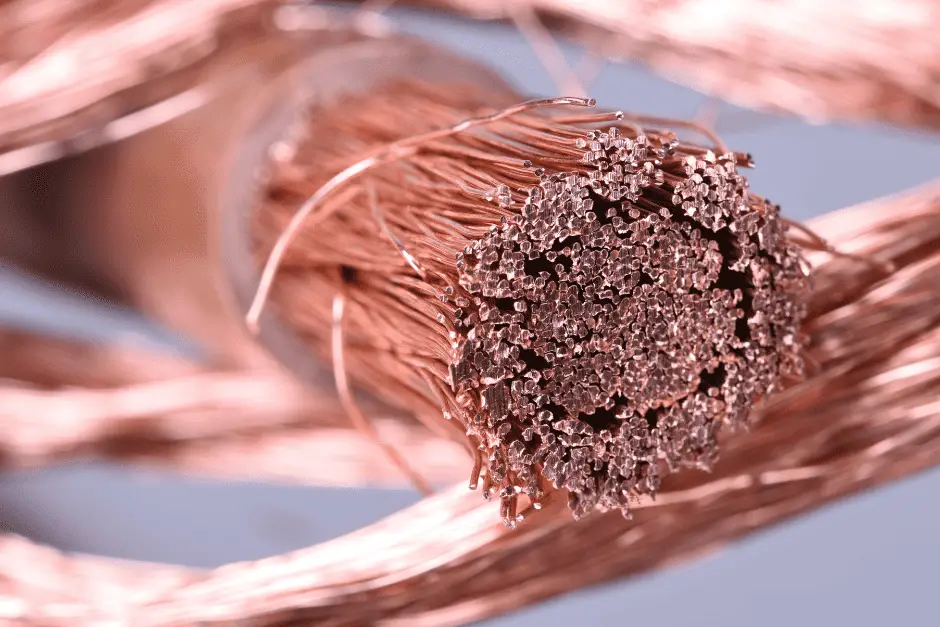

Copper is a highly conductive and ductile metal, making it extensively used for electrical wiring and electronic components. Its natural corrosion resistance and antimicrobial properties make it suitable for plumbing and water distribution systems. Copper is also used in the manufacturing of various alloys, such as brass and bronze, which enhance its properties and expand its applications in the industry.

Titanium

Titanium is a strong and lightweight metal known for its excellent corrosion resistance and high melting point. It has a wide range of applications, primarily in the aerospace, medical, and automotive industries. In the aerospace sector, titanium is used to create strong, lightweight components for aircraft and spacecraft.

In the medical field, its biocompatibility makes it a popular choice for surgical implants, dental applications, and prosthetics. In the automotive industry, titanium’s strength-to-weight ratio and heat resistance make it suitable for high-performance parts like exhaust systems and engine components.

Key Properties and Applications

Corrosion and Heat Resistance

Metals with excellent corrosion resistance are invaluable for engineering and manufacturing purposes. A widely used metal with corrosion-resistant properties is zinc, commonly applied for galvanization of steel and exterior applications such as roofs, windows, or wall panels. Additionally, metals like tungsten have exceptional heat resistance, with a melting point of 3,422 °C and a boiling point of 5,930 °C, making it suitable for use in high-temperature applications and alloys ^1^.

Conductivity

When it comes to electrical and thermal conductivity, some metals are better suited for specific applications. Good conductors of electricity, like copper and aluminum, are ideal for cables, wires and electrical systems due to their high conductivity and lower rate of power loss. The ability to transfer heat efficiently is vital for materials used in heat exchangers and radiators.

Strength and Density

Metals with high strength and density make them ideal for use in the construction, automotive, and aerospace industries. For instance, steel is a strong and durable material that can withstand heavy loads and is widely used in the construction of bridges and buildings. Tungsten, with 19.25 grams per cubic centimeter density, is equal to that of uranium and gold, displaying outstanding hardness and tensile strength. These properties make tungsten an excellent choice for manufacturing cutting tools and industrial machinery components.

Malleability and Ductility

Certain metals exhibit properties such as malleability and ductility, allowing them to be deformed or stretched without breaking. These characteristics make metals like gold, silver, and aluminum ideal for forming into intricate shapes such as wires, sheets, or delicate designs in jewelry. They can be easily manufactured into components and structures as their ability to be rolled, drawn, or pressed into thin sheets or complex shapes enhances design flexibility and reduces fabrication costs.

Common Metal Alloys

Stainless Steel

Stainless steel is a widely used alloy that is primarily composed of iron, chromium, and nickel. It is known for its excellent resistance to corrosion and staining, making it a popular choice for various applications. This metal alloy comes in different grades, with varying amounts of chromium, nickel, and other elements like molybdenum and carbon. Some common uses of stainless steel include kitchen appliances, cutlery, automotive parts, and medical instruments.

Bronze

Bronze is an alloy mainly composed of copper and tin. It can also contain other elements such as phosphorus, zinc, or silicon, which can further improve its properties. Bronze is characterized by its exceptional strength, durability, and resistance to corrosion. This metal has been used for thousands of years for various purposes, including the production of weapons, tools, and sculptures. Today, bronze is commonly used for making bearings, electrical connectors, and decorative artworks.

Brass

Brass is another copper-based alloy, typically containing varying amounts of zinc. The proportion of copper and zinc in brass determines its properties, such as strength, ductility, and corrosion resistance. In some cases, small amounts of other elements like lead or silicon may be added to improve machinability. Brass has a wide range of applications, due to its versatility in terms of mechanical and physical properties. It is commonly used for musical instruments, hardware fittings, and decorative items.

Alloy Steel

Alloy steel is a type of carbon steel that contains additional alloying elements such as chromium, nickel, molybdenum, cobalt, and more. These elements are added to enhance specific properties like strength, hardness, or resistance to wear and corrosion. Alloy steels are classified into two categories: low-alloy steels and high-alloy steels. They can be found in various applications, including automotive parts, construction materials, and machinery.

Throughout the industry, different types of metal alloys are used to achieve specific properties and characteristics for various applications. These common metal alloys – stainless steel, bronze, brass, and alloy steel – each possess distinct benefits, making them suitable for a wide range of purposes. Whether it’s in construction, automotive, or decorative industries, these alloys play a crucial role in enhancing the performance and durability of the resultant products.

Carbon Content and Types Of Steel

When discussing steel types, it is crucial to understand the importance of carbon content. Carbon plays a significant role in determining the properties and applications of different types of steel. This section will focus on three primary types of steel based on their carbon content: Low Carbon Steel, Medium Carbon Steel, and High Carbon Steel.

Low Carbon Steel

Also known as mild steel, this type of steel contains less than 0.25% carbon. Low carbon steel is known for its excellent weldability and formability. It is widely used in a variety of applications due to its versatility and affordability. Some common uses include:

- Automotive components

- Piping and tubing

- Construction materials, such as I-beams

Low carbon steel’s properties include a lower tensile strength and hardness compared to higher carbon steels. However, it typically showcases impressive ductility and malleability, making it suitable for manufacturing processes that require bending or shaping (source).

Medium Carbon Steel

Medium carbon steel has a carbon content ranging from 0.3% to 0.5%. These steels display a balance between the ductility of low carbon steel and the strength and hardness of high carbon steel. As a result, medium carbon steel is often used in applications that demand strength and durability without compromising too much on forming capabilities. Some common examples include:

- Gears

- Shafts

- Connecting rods

- Machinery components

Due to its higher carbon content, medium carbon steel can be heat treated to increase hardness and tensile strength while retaining a reasonable degree of ductility (source).

High Carbon Steel

High carbon steel, sometimes referred to as tool or spring steel, has carbon content greater than 0.5%. This type of steel is known for its high strength, hardness, and wear resistance. Consequently, high carbon steels are frequently employed in applications where toughness and wear resistance are critical factors. Some typical uses include:

- Springs

- Knives and hand tools

- Taps and milling cutters

- Wire-drawing dies

However, high carbon steel’s elevated carbon content reduces its ductility, potentially making it more difficult to work with and more prone to brittleness. Moreover, it is less resistant to corrosion compared to low or medium carbon steel (source).

Industry-Specific Applications

Engineering and Construction

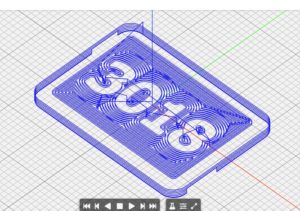

In the engineering and construction industry, various types of metals play a pivotal role. For instance, wrought iron is used in constructing fences, gates, and other ornamental structures due to its corrosion resistance and malleability. This metal can be easily worked on at room temperature, making it suitable for intricate designs. On a larger scale, steel, a strong and versatile material, is commonly used in the construction of buildings, bridges, and monuments like the Eiffel Tower. Additionally, welding and CNC machining are essential techniques in joining and shaping metal components within this industry.

Automotive and Transportation

The automotive and transportation sector heavily relies on various metals. Steel is a predominant material in vehicle construction due to its high strength and cost-effectiveness. Lightweight metals, such as aluminum and magnesium, have gained popularity in recent years as they contribute to improved fuel efficiency without compromising structural integrity. These metals are also found in components like engines, wheels, and body panels. In terms of electrical conductors, copper and aluminum are widely used in wiring systems for power transmission in vehicles and other transportation modes, such as trains.

Electronics and Technology

Metals play a vital role in the electronics and technology industry. Many devices, including smartphones, computers, and light bulbs, require metals like copper, gold, and silver for their excellent electrical conductivity properties. For semiconductor applications, metalloids like silicon are essential, while nonmetals, such as carbon, are incorporated in cutting-edge materials like graphene.

In addition to conducting electricity, metals like aluminum and copper are also used as thermal conductors to dissipate heat in electronic devices. Other specific applications involve magnetic metals, like iron and nickel, in data storage devices and speaker systems, as well as non-magnetic metals, such as diamagnetic metals, which can repel magnetic fields and protect sensitive electronic components.

In conclusion, the metal industry plays a significant role in various sectors, including engineering, construction, automotive, transportation, electronics, and technology. Each application often requires a specific type of metal or alloy to achieve the desired performance, leading to continuous research and development within this field.

Historical Role of Metals

Bronze Age

The Bronze Age marked a significant period in human history, as it was the first time people began using metal for tools, weapons, and decorative purposes. Bronze, an alloy of copper and tin, was the primary metal used during this time. The discovery of metals played a crucial role in the development of human civilization, transforming agriculture, transportation, and the arts and crafts, forging the pathway to modern society.

Bronze offered several advantages over the previously used materials like stone and wood, including:

- Higher durability: Bronze tools and weapons were more durable and less likely to break or wear out.

- Improved functionality: Bronze items had a higher melting point, allowing them to be shaped into more intricate and complex forms.

- Increased trade and cultural exchange: The demand for copper and tin led to the growth of trade networks, fostering cultural exchange and the spread of new technologies.

Industrial Revolution

The approach of the Industrial Revolution brought about significant changes in the use of metals, particularly in the manufacturing sector. One pivotal example is the increased production of pig iron, a product of smelting iron ore, which became an essential material for the construction of railways, wires, pipes, shafts, and valves.

During this period, the demand for metals led to numerous innovations, such as:

- Mass production of steel: The Bessemer process and the development of open-hearth furnaces revolutionized steel production, making it more affordable and easier to produce.

- New metal alloys: The Industrial Revolution drove the development of new metals and alloys, including tools made from shock-resisting tool steel containing constituent metals like molybdenum, vanadium, cobalt, and tungsten.

- Widespread application of metal engineering: Advances in metallurgy expanded the use of metals in the automotive, shipbuilding, construction, and packaging sectors, transforming industries and shaping modern society.

The historical role of metals in civilization has been transformative, ushering society into new eras of technological and cultural advancement. From the Bronze Age to the Industrial Revolution, metals have played an essential part in human progress.

Other Notable Metals

Gold

Gold is a highly valued metal known for its stunning yellow color, malleability, and resistance to corrosion. It is the most non-reactive of all metals and doesn’t tarnish or corrode easily. Gold has numerous applications, including jewelry production, currency, and as a store of value in investments. Additionally, the conductivity and resistance to rust make gold an essential component in various electronic devices, such as computers and smartphones.

Gold is often combined with other metals to form alloys, which improves its hardness and durability. Karat is the term used to measure gold purity, with 24-karat gold being the purest form. Lower karatage indicates higher levels of other metals mixed in the alloy.

Silver

Silver, another well-known precious metal, is known for its aesthetic appeal and conductivity. It is highly reflective and conducts electricity better than any other metal, making it critical in numerous applications. Like gold, silver is utilized in jewelry and as a form of currency, with coins often produced from silver.

In addition to its use in jewelry and coins, silver has various industrial applications, such as electrical components, batteries, solar panels, and even in the medical field because of its antibacterial properties. Silver also plays an essential role in photography due to its light-sensitive characteristics.

Platinum

Platinum is a rare, dense metal that is highly resistant to corrosion and oxidation. It is often found in jewelry and is sometimes used as an alternative to gold in wedding rings due to its durability and appealing luster. Platinum is hypoallergenic, making it an ideal choice for individuals with sensitive skin or allergies.

Apart from its use in jewelry, platinum has numerous critical applications, particularly in the automotive industry. Platinum is essential in the production of catalytic converters, which help control the emission of harmful gases by converting them into less harmful substances. Additionally, the metal is employed in the manufacturing of laboratory equipment, fuel cells, and electronic components.

In summary, gold, silver, and platinum are well-known metals with unique properties and various applications, ranging from jewelry to electronics and automotive components. Their properties, such as conductivity, corrosion resistance, and aesthetic appeal, make these metals particularly prized and useful across several industries.