What is the Spur Gear Factory?

Spur Gear Factory is your opportunity to download a collection of G code files to machine your own set of spur gears.

All the G-code files have been programmed to be used on a budget cnc engraver.

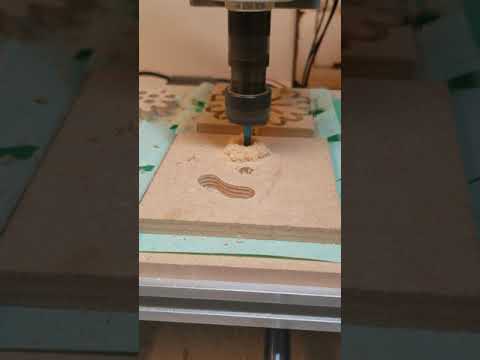

Load them straight into candle, universal gcode sender or Mach3, set up your stock, offsets and end mill, then press ‘send’.

These files are perfect for a newbie with a 3018 cnc router, a quick and easy project to inspire you to create.

The G Code is created using genuine spur gear geometry, meaning they will mesh together perfectly. You can use them to enable mechanical movement in a bigger project, letting you get as creative as possible.

If you have a more capable cnc machine these G Code files are suitable to make the Spur Gears in aluminum, just use good quality end mills suitable for metals

What do you get?

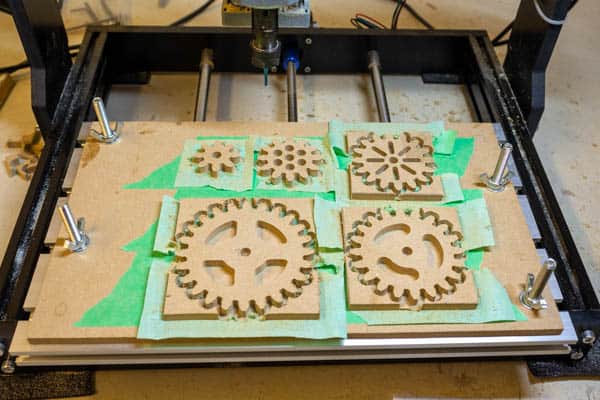

- G Code files to machine 7 spur gears with various tooth count + 1 gear rack

- PDF Set up instructions

- 25 individual g code programs with an approx total runtime of 4-1/2 hrs

- A universal program for a .25” center hole, use this for each gear.

Machining Processes

- I tried to vary the machining processes to give a beginner an insight into the different approaches you can take when machining a part. These include:-

- Circular interpolation ramping

- Linear ramping

- Contour profiling with step downs (pecking)

- Rest machining

- Peel milling

Included Spur Gear G Code

G code for 8 Tooth Spur Gear

The smallest gear in the collection with an outer diameter of 1.18” or 30mm

G code for 12 Tooth Spur Gear

This gear is big enough to include detail around the center hole. It has an outer diameter of 1.65” (42mm)

G code for 16 Tooth Spur Gear

This gear features slots around the center hole. It has an outer diameter of 2.125” (54mm)

G code for 20 Tooth Spur Gear

This gear has curved slots around the center hole, created using peel milling. It has an outer diameter of 2.6” (66mm)

G code for 24 Tooth Spur Gear

This gear has triangular(ish) shaped cutouts around the center hole, also created using peel milling. It has an outer diameter of 3.07” (78mm)

G code for 28 Tooth Spur Gear

This gear has three large triangular(ish) shaped cutouts around the center hole. It has an outer diameter of 3.54” (90mm)

G code for 32 Tooth Spur Gear

This gear features five segmented shaped cutouts around the center hole. It has an outer diameter of 4.02” (102mm)

G code for 12 Tooth rack Gear

This completes the line up. An addition which will be useful for converting circular movement of the gears to linear movement. This will give you extra options for your projects. Make several and line them up end to end to increase the length.

It is 4.45” X 0.49” (113mm X 12.5mm)

F.A.Q.

Will my CNC be able to read this G Code?

The G code has been post processed to run on any GRBL controlled machine. All programs have been tested using Candle and Universal G code sender.

I also tested and successfully ran them using Mach3.

You can confirm if the G Code will work on your CNC by downloading and running my free G Code spider program. If you don’t have any problems with those files, then they will run perfectly.

Note, if you are using Candle software;

I have had an issue recently where Candle is not remembering my last used offsets and the restore origin command has not been working. If this happens to you, I have published a workaround for re-establishing your previously stored offsets. Candle software offset problem.

What type of stock do you need?

You will need to use some 1/4” or 6mm thick wood sheet. I used MDF because it is flat, perfect for using the masking tape and super glue technique for holding stock to the table.

What size of End Mills are needed?

You will need a ⅛” (.125”) end mill and a 5/64″ (.078) or (2mm) end mill. I used two of the tools from the Genimitsu set. These are available on Amazon, click the link or picture below to check the current price and availability. (Affiliate Link)

- Cutting Edge Diameter: 0.8 - 3.0mm (0.8/1.0/1.2/1.4/1.6/1.8/2.0/2.2/2.4/3.0mm), 10Pcs.

- Hard Steel: With sufficient flexural strength and wear resistance, which ensure high work efficiency.

- Material: Using ultra-fine grained carbide material, with good milling and cutting performance.

- Advantage: Sharp cutting edge, milling, hole and plate edge, clean surface, neat, no glitches.

- Application: PCB, SMT, CNC, Mold, plastic fiber, carbon fiber, hard wood, printed circuit board, and other precision parts processing.

You can use any other type of end mill just as long as they are the correct diameter.

How do I hold the stock to the cnc machine table?

The easiest way to clamp your stock is by using the masking tape and super glue method.

To do this you will need masking tape and super glue !

(If you have never used the masking tape method before, it is explained in the set up instructions supplied with the G code.)

What type of Masking tape works best?

Any masking tape should work.

What type of Super glue is needed?

Make sure you don’t get thin viscosity super glue, it soaks through the tape and into the wood.

Not good !

I use medium viscosity but thick would probably work too.