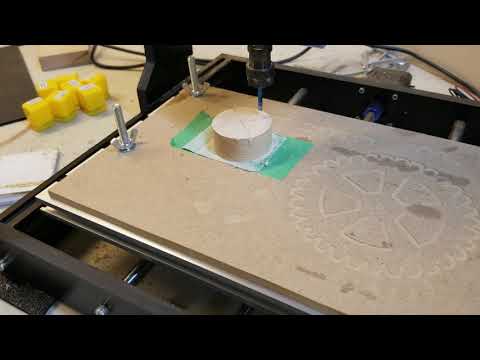

I was a little dismayed to find that Candle software has started to cause me issues with regard to remembering my last used datum offsets.

If you have tried running any of my G Code programs and had this issue it could be confusing as it can cause problems when following my instructions for running the programs.

So, if you have had issues with subsequent programs running out of position and not matching with your previous program(s), you need to read this. (video demonstration at the end of this article).

Candle should restore your previous offsets

If you are running multiple programs for a single project on your cnc machine you should be able to switch off your machine and return later and carry on from where you left off.

Candle should remember your previous offset positions enabling you to run your next program and it should match with your previously run programs.

This is done by keeping a fixed home position and returning your machine to this home position before it is switched off.

When reopening Candle the previously set offset positions should be remembered and your machine should be ready to carry on finishing your project.

Candle is not restoring your previous offsets

Candle has been storing my offsets just fine up until my last project when it has been pulling up some random machine coordinates on restart. Obviously this is a problem, my next programs will not match the position of the part on the table if I try to run them.

I don’t know why this is happening and how to prevent it, but I do know an easy work around, keep on reading to learn how…

How to fix this issue

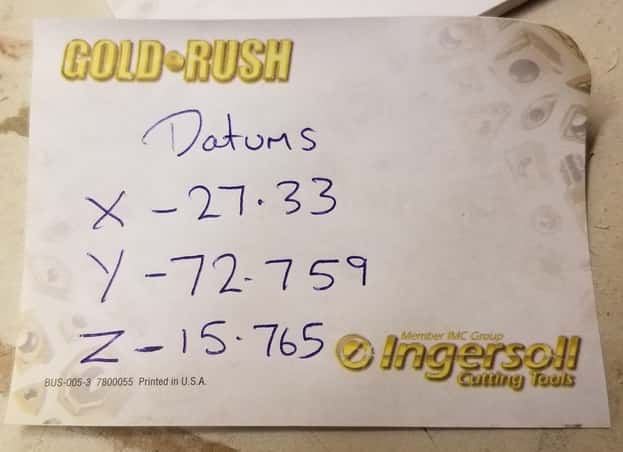

The first action you have to take is to write down your machine coordinate offsets when you initially set them, prior to running your first program.

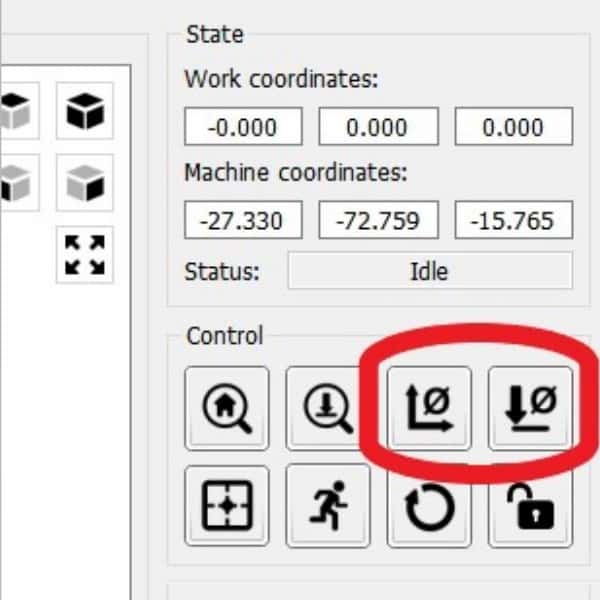

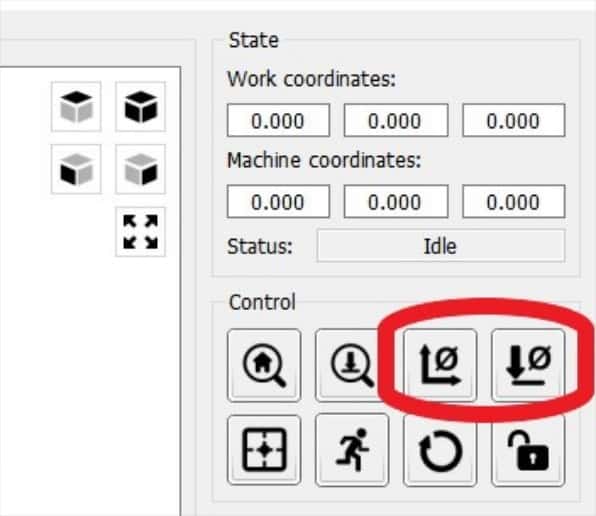

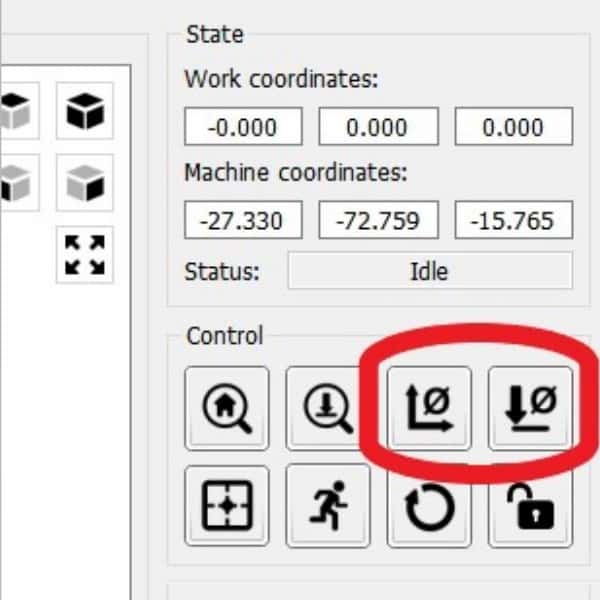

When positioning your spindle/tool at your desired position, press the datum set buttons to set your datums.

When set, don’t move your machine, first write down the numbers in the machine coordinates boxes, these are your offsets positions.

Once you have written them down, you can home your machine.

Now you have recorded your offset positions, when you close down Candle and switch off your machine you can check if they match when the machine and Candle software are powered back on.

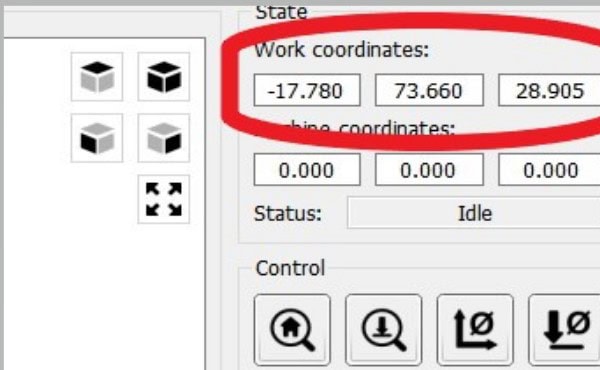

What to do when your offsets don’t match

When powering back up and your offsets are different, the first action to take is to NOT move your machine.

It should be still at its home position, so all you do now is reset all your datums so both your work coordinates and machine coordinates read ZERO.

Then you need to move your machine by your offset position distances; this will reposition the machine at your previous datum position.

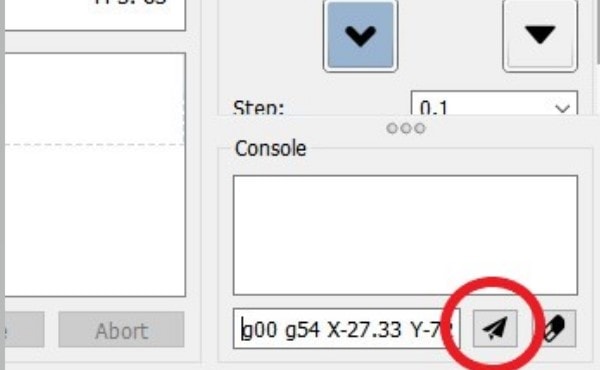

This is done by using the console function.

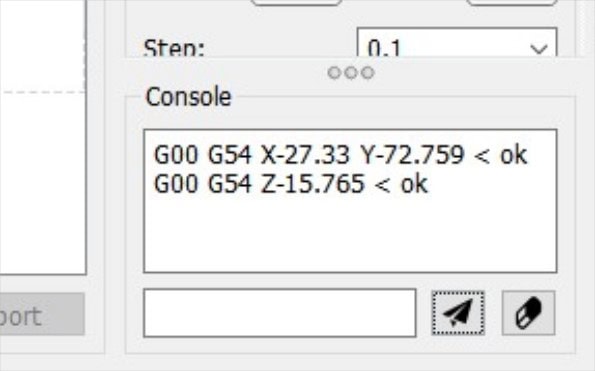

Using my offset positions (use yours, not mine!) I type in ‘G00 G54 X-27.33 Y-72.759’ in the console window and press the ‘arrow’ button. The machine will now move above its datum position.

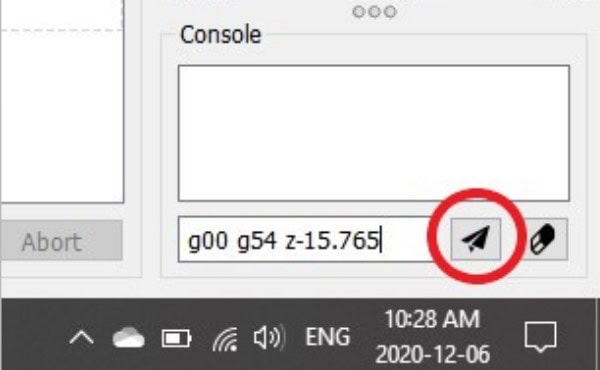

Then type in ‘G00 G54 Z-15.765’ and press the ‘arrow’ button. The Z axis will now move to your previous Z datum position.

Now reset all three of your Datums by pressing the Datum set buttons. Your datums are now reset to where they were initially.

Your machine work coordinates have been reset and you can now send your machine back to its home position.

Once you have read through this article and tested it out on your machine it should be quite easy to remember.

It should also give you a good understanding of how the machine reference position (machine coordinates) and work offset positions (work coordinates) work together.

With more sophisticated software, e.g. Mach3, your offsets are stored in an offset table and can easily be changed by just retyping them back in. (Not that Mach3 has ever given me this problem!)

It is not possible to type the offsets back in with candle, that is why you have to go through this process to re-establish them.

How to set your safe button as your home command

You can learn how to set the home command in Candle by reading through my Candle software article, but I will recap the process here;

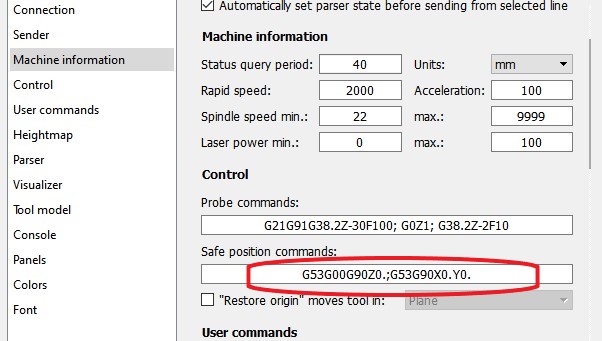

‘Safe Position’ will move your machine axes as specified in the settings dialog box under safe position commands.

This can be used as your home position button if your machine does not have home/limit switches.

Just open the settings box and type G53G00G90Z0.;G53G90X0.Y0. in the safe positions command box. (you can copy and paste it from this text)

You can now press this button every time you need to send your machine to its home position.