A Guide to ‘Machining’ parallel sets

What are Parallels?

Precision parallels or ‘parallel sets’, are blocks of steel that are machined to a flat rectangular shape and produced in matching pairs.

They are hardened and then ground to an exact size with each opposite face being exactly parallel to each other.

This is typically only done with the four main faces and not the ends.

What are machining Parallel sets used for?

The main use for a typical set of parallels is to elevate your part up in a vise. They will keep your part parallel to the floor of the vise and table of the milling machine.

This will enable you to produce a part that is flat and make it measure the same thickness along its length.

Elevating the part with parallels also enables you to mill or drill all the way through a part without hitting the vise or table of your milling machine.

They can also be clamped directly to a machine table to produce a repeating setup when machining multiple parts.

How are machinist Parallel sets used?

There is no skill needed in using them, just make sure they are clean and not sat on any chips or debris. Also make sure the part you are sitting on them is clean and free of chips.

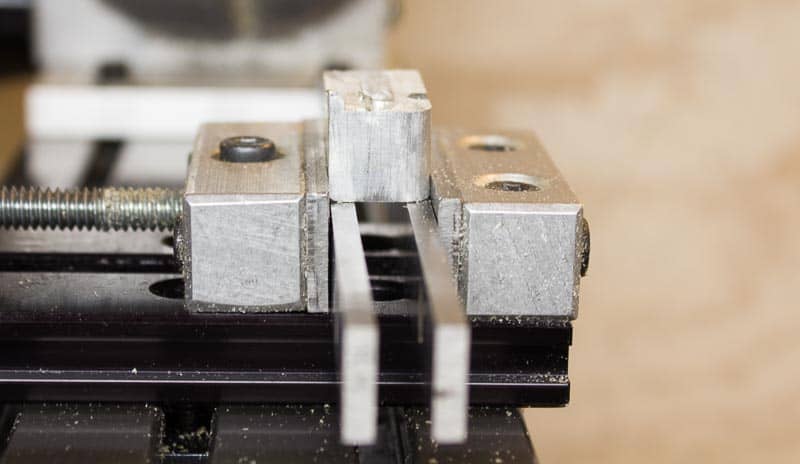

When using them as vise parallels, the part is placed on them and the vice is tightened, usually not fully tight at first. Then the part is hit with a soft blow mallet to make sure it has not lifted when the vise is tightened.

Check the part is seated by trying to slide the parallels.

If they can’t be moved, the vise can be fully tightened and checked again before continuing with the machining operation.

Tips for using parallel sets

One aspect of using parallels is their annoying habit of falling over.

You always have to ensure they are stood up vertically and ideally against the vise jaws.

There are a few ways to do this, the most obvious is to use small springs. Positioning a couple of springs in between will keep your parallels pushed up against the vise jaws when you are opening and closing the vise.

Another method of keeping them apart and upright is by using a bent piece of spring steel. Machine shops usually have lots of wooden crate banding thrown into the garbage. This banding is made from a thin flexible spring steel.

Cutting off a strip and bending into a ‘Z’ shape will create a spring to keep your parallels apart. This has the advantage of letting your vise jaws close a lot further than using traditional coiled springs.

Wavy Parallel sets

Wavy parallels are designed to support very thin parts in your vise. They are made from thin spring steel which can be compressed in a vise.

This has the same effect as using springs to keep your parallels apart except the parallels are the springs.

Adjustable parallel sets

Adjustable parallels are generally not used for supporting parts in a vise even though you could use a single one for that purpose.

They do not come in pairs and it would be tricky to set two to the same height.

They have various uses including measuring the width of a slot or setting a pair to use as ‘go’ ‘no go’ gauges or as an adjustable gauge block.

Anytime tools 10 piece machinist thin parallel sets

- Made of high grade alloy steel, hardened and ground. 2 holes in each parallel.

- 10 1/8" Thin matched pairs in set. +/- .0002 Parallelism in height.

- High quality precision ground alloy Hardness: 54-58 HRC .Measurements: 6" long x 1/8" thick

- Two holes in each bar. Increments in 1/8" from 1/2" to 1-5/8".

- Set includes a pair of each height: 1/2, 5/8, 3/4, 7/8, 1, 1-1/8, 1-1/4, 1-3/8, 1-1/2 and 1-5/8

Accusize Industrial Tools 1/8” Thickness 10 Pairs

- 1/8" thick matched pairs. 6" length

- Our most pUltra-Precise Dimensions: Each set includes 10 matched pairs with exceptional accuracy, featuring +/-0.0002" parallelism and +/-0.0001" height.opular parallel set, this set includes 10 matched pairs with ultra-accurate dimensions

- Made from high quality alloy steel

- Hardened and ground

- Accracy: +/-0.0002" parallellism

Accusize Industrial Tools 9 Pairs Wavy Parallel Sets

No products found.

Accusize Industrial Tools 6 Pair Adjustable Precision Parallel Sets

- Size range: 3/8" to 1/2", 1/2" to 11/16", 11/16" to 15/16",15/16" to 1-5/16", 1-5/16" to 1-3/4", and 1-3/4" to 2-1/4"

- Length range from 1-3/4"to 5" Closed

- Quickly Adjustable, and locked with set screws for micromoment.

- For layout, inspection, stop work, set-up, etc.

- Thickness: 7mm