My aim with this article is to help you decide which type of benchtop hobbyist cnc milling machine will be the best for you.

These types of machines are also known as desktop cnc mills.

I will be discussing the following types of machine.

- Small cnc engraving machine

- Cnc router

- Benchtop Cnc mill

Which is the Best benchtop cnc milling machine?

The title above is generally what people ask when they are trying to decide which make of mill to buy. What you should be asking is, what do you want to create, what type of material will you be using and what size are the items you want to make or modify.

Decide what you want to make and choose a cnc machine based on your needs.

The information in this article will help you with that decision so that you can make a more informed choice.

Which type of cnc machine is the best for your needs?

Generally speaking, you get what you pay for with a cnc machine, just like most things in life.

If you just want to learn and try a new hobby then maybe a small cnc engraving machine might be just what you need.

What is the best wood cnc machine?

You may want to make larger decorative pieces in softer materials like wood to create your own products to sell as a side hustle. In this case a cnc router would be the direction to go in.

These machines are the largest type of home based machine available. They use the gantry mill type of design as this gives you an effective milling area almost the size of the machine’s footprint.

What is the best small cnc machine?

The other main choice is a benchtop cnc mill, these are small cnc machines designed to create projects in metal.

They are a lot more sturdy than the gantry type of mill and usually built with steel and aluminum components. They look just like their industrial counterparts but shrunk to fit on a bench.

They are capable of machining other materials as well but the size of the components you can make will be considerably smaller than a gantry mill.

As you can tell the size of the machine you choose is usually a trade off with their capabilities. If you need bigger and better the cost will increase accordingly and it will be getting away from the hobby area.

How much does a small cnc machine cost?

This is a question that gets asked a lot.

A small cnc engraver will cost from around $200 to about $500.

A cnc wood router will cost from around $800 to $2000 plus.

A benchtop cnc mill that is capable of machining metal will cost from around $2500 and up.

Obviously the more you spend the better and more capable the machine will be.

Best Small cNC engraving machine

This will be the least costly choice and a good type of machine to buy if you just want to learn the basics of cnc machining and programming.

How accurate are they?

Most cnc machines, even budget priced machines can be very accurate. Machines like these will be accurate to within a few thousands of an inch. They will be good enough to produce accurate patterns and profiles in soft materials such as wood or plastic.

The issue with these type of cnc machines is that accuracy will suffer quickly if any amount of force is applied to them.

They are called engravers for a reason, they are only capable of very small cuts with small cutters.

They are not designed for producing engineered parts, just decorative items. Artistic creativity being a positive selling feature for this type of machine.

How reliable are they?

If you buy a budget priced item you may experience reliability issues with the electronic components. The design of the mill itself may not last if plastic components are used.

Be prepared to have to maintain or upgrade these types of machines.

Can they cut metal?

No. If you want to make any type of metal component, even soft metal, do not buy one of these types of machine.

The best it will do is engrave (scratch) aluminum.

What can’t they do?

Most tasks that you would want a cnc machine to do is exactly what these budget machines don’t do. Unfortunately.

These really are only hobby machines designed to be educational and fun.

Can these machines be used with a laser engraver?

Yes! In fact these machines are the perfect match for doing small laser engraving work. They can be bought from the manufacturer with a laser system included. This does increase the cost quite a lot though. (Laser Module Review Here).

This system would be perfect if you built radio control boats or aircraft. The wooden formers or wing ribs could be cut on a machine like this. Enabling you to design your own models on a cad system and then accurately laser cut them out. (LaserGRBL software tutorial here)

Size Restrictions

These small engravers can have a good sized working area due to the gantry type design. Typically they have about 12” by 6” of working area. The one weakness is in vertical travel, (z axis), they generally have less than 2” of movement.

This gets reduced even more when the length of the engraving tool is factored in. This shouldn’t be a concern if you intend to use it for what it is designed to do though.

Choosing a machine with an ER collet spindle would be a good choice. They enable a varied amount of tooling sizes to be used in a compact size.

Summary

I have a full review and setup tutorial of the popular 3018 Cnc engraving machine. If you are considering one of these machines you should check it out.

- Accurate in soft materials only

- Good for creative or decorative projects

- Fun and educational at an affordable price

- Perfect for laser engraving/cutting smaller parts

- Cannot cut metal, at all

- Not designed to produce engineered parts

- Very little rigidity and strength

- Low torque type of spindle motor

Best CNC Router

As the name suggests a cnc router is a wood router mounted in a cnc gantry mill. These can be much larger than the engraving machines I previously described.

Using interchangeable milling cutters, they can be programmed to produce elaborate wooden reliefs and other carpentry projects that would be almost impossible to do by hand.

I show a simple project in the article ‘Fun Cnc Project‘ which would be perfect for a small (or large) Cnc router.

How accurate are cnc routers?

Cnc routers can be very accurate when milling wood. The potential accuracy of any cnc machine is determined by its stepper motors. Inaccuracy can occur with deficiencies in their design.

If the router is made from wood, as some are, the strength of the machine can affect how accurate the machine can cut. If there is flex in the structure under load, the accuracy will be terrible.

Check out how much a machine weighs. If it is heavy it is likely to be sturdy. If it is sturdy it is more likely to be accurate.

How reliable are cnc routers?

A routers reliability is dependant on how well it is designed. The spindle is usually a router clamped onto the z axis so having a router from a recognised manufacturer will improve reliability.

Reliability and good design will improve with cost, so if you purchase one make sure you get the best you can afford. It will pay off in the long run.

Can cnc routers cut metal?

Yes and No. Some manufacturers will list “soft metal” in their info but they don’t elaborate on how well it will do it. They don’t even specify what “soft metal” is. So I would say no, for the diy machines for hobby use.

If you want a larger gantry mill to be able to machine metal you have to spend a lot of money and use a high end spindle motor. A wood router attachment is not going to “cut it”:)

What can’t a cnc router do?

Lack of quality is a big factor on what these machines cannot do. A typical hobby machine that will cost less than a thousand bucks will not cut metal. They will be “assemble yourself” kits that use a commercially available hand router as a spindle.

For this reason they will be only capable of milling wood or plastics etc.

The gantry design also minimizes the z travel, limiting the vertical height of any project you may want to do.

Can cnc routers be adapted to use a laser engraver?

Yes, there are kits available to add a laser to a cnc router. This will make an efficient alternative to a small endmill when cutting out profile shapes in thinner sheet materials.

If you want to use a laser exclusively you will be better off buying a dedicated laser cutting machine instead.

There are certain safety considerations when using a laser that a laser cutter will address more effectively.

Size restrictions for a cnc router

The z axis is the main size restriction with cnc routers other than that it all depends on how much money you have to spend. Also you will need to consider how much room you have to house your router.

If you have a basement workshop you will need to be able to get it in there. If it is just a hobby size router I doubt this will be an issue.

Summary

- Good for larger projects

- Perfect for woodworking projects

- Easily upgrade the spindle for improving capabilities

- Budget entry level d.i.y. Kits available

- Lots of online information and support available

- Entry level routers limited to milling wood

- More capable routers can be expensive

- Routers mainly limited to making flat or “relief” type projects

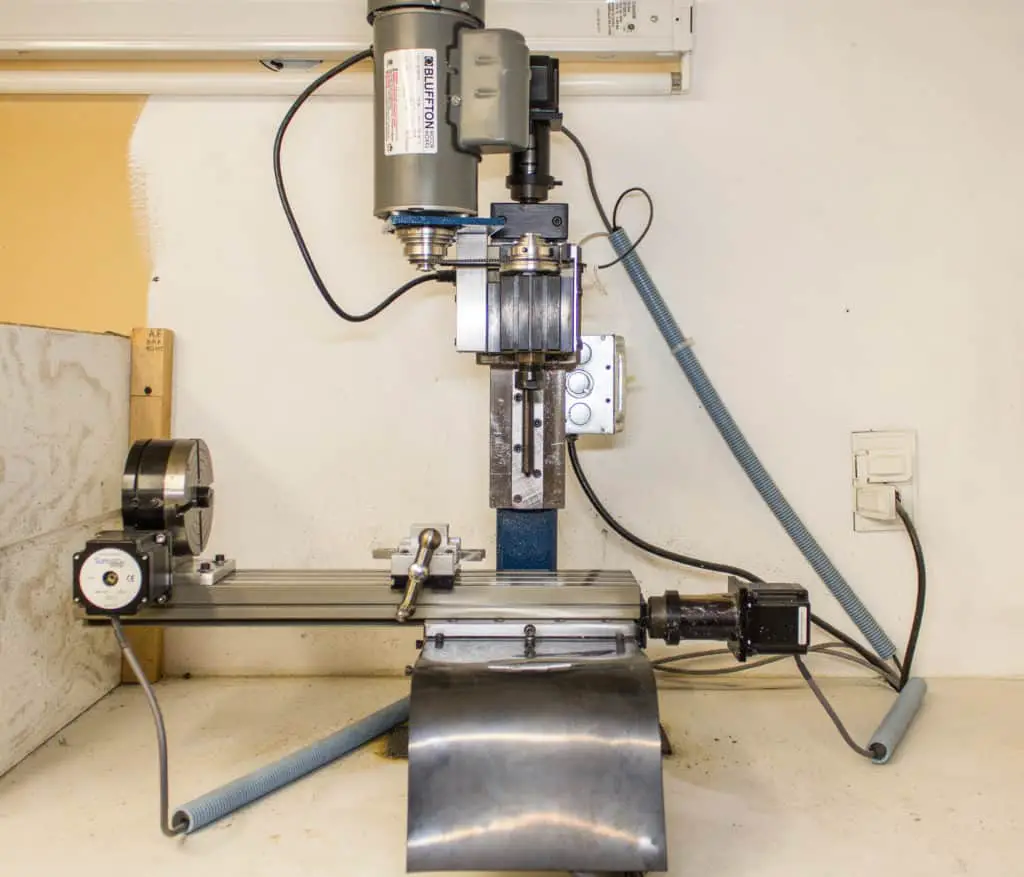

Best Desktop cNC mill

If you are going to be producing most of your work in metal then a good desktop cnc mill will be the best choice. The structural components will be made of steel providing the machine with the rigidity it needs.

- Sherline 5400-CNC Factory installed CNC couplers + the "A" package. INCH

There is a varied choice of cutters available for this type of machine making them the most versatile machine available. The spindle motors have more power than the usual router mill enabling larger tooling to be used.

Slower spindle speeds are achieved by gearing down the spindle which will provide the lower rpm and torque needed to mill aluminum and steel.

How accurate are desktop cnc mills?

A good desktop cnc mill is very accurate and can machine to within .0005” (.0127mm) easily. As long as the machine is well maintained it will last for years. Well established manufacturers will be able to supply replacement parts for any of the machines mentioned in this article.

The rigidity of the machine plays a large part in maintaining accuracy and by design this type of machine will be very solid.

The accuracy of these mills will justify the need for digital calipers in most of your projects.

How reliable are desktop cnc mills?

Like any of the mills I have discussed in this article, if they are kept clean and well maintained they will be very reliable. The biggest reliability issue with any hobby cnc will be software problems.

Most people using a windows PC have encountered software update issues, so making sure you have the most stable version of your machine control program will be advisable.

Notice I said “most stable” and not the “latest version” of your software. If it works for your PC don’t update to the latest version unless you need to. Let other people test the latest version.

One important setting you need to change on your PC is to prevent your USB ports from going to sleep after a set amount of time.

This is important to prevent your machine from stopping mid run.

Can a desktop cnc mill cut metal?

As already mentioned, this type of machine is designed to cut most types of metal. They can mill aluminum all day long and consistently produce multiple parts.

Learn how to establish your feeds and speeds and you shouldn’t have any problems.

Steel is also no problem for this type of machine but a little more experience will be needed to ensure you have the correct spindle speeds and feeds. Knowing what to adjust when experiencing issues will also be a big benefit. I have a G code programming for dummies article that will help get you started on your cnc programming education.

The majority of hobby cnc mills will not be equipped with a coolant system which also can be an issue when milling steel.

There are many coolant d.i.y. setups shown online that can be copied for this purpose.

The process involves setting up the machine in a large metal tray with a drain going below the bench into a catch tank with a pump in it. The pump then recirculates the coolant back up to the machine and through a plastic coolant pipe aimed at the tool.

The basic use for the coolant is to transfer the heat away from your cutting tool keeping it cool which extends its life. It will also assist in washing away the chips from the tool preventing it from clogging up and potentially breaking.

Aluminum can benefit from using coolant but you can get away with using WD40 and a quick blast of compressed air every now and again to clear the chips. The only downside to this is having to “babysit” the machine while it runs.

What can’t desktop cnc mills do?

A desktop cnc mill is a small version of an industrial cnc machine but they lack all but the most basic functionality of their bigger brothers. One example is the spindle cannot be “timed” or orientated to match the machines movement. This type of functionality enables machines to tap holes and do boring bar cycles.

This is not a problem though because desktop mills are only capable of producing small parts so not being able to tap threads, for example, is not a deal breaker.

Larger threads can be machined with a threadmill by interpolating a circle while ramping up or down in the z axis.

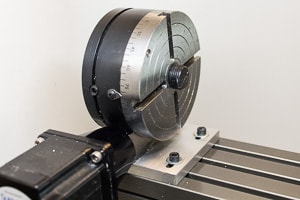

Can desktop cnc mills have more than three axes?

Yes, I have a 4th axis for my cnc desktop mill enabling a round part to be machined around its axis.

I know of at least one 5 axis desktop cnc mill called Pocket NC. You can check it out through this link.

Size restrictions of a desktop cnc mill

The big advantage with this type of mill over a gantry type mill is the available z axis movement. The disadvantage is usually in the amount of y axis travel, this is reduced due to the design.

To get more movement in the y axis, the spindle would have to overhang the table by a longer distance. This would reduce the rigidity of the machine. I own a Taig mill and the axis distance travels are:

Travel in X axis 12 in. (Model 2019)

Travel in Y axis 5.5 in

Travel in Z axis 6.0 in

Table dimensions 3 1/2 x 18.4 inches (Model 2019)

You can check out the mill I own and use through this link.

Most desktop mills have a similar amount of usable work area, you will have to try and consider what you will need to help you choose the best mill for you.

Summary

- The ideal solution for machining metal parts at your home workshop

- Accurate enough to make engineered metal components for working assemblies

- Lots of different types of tooling available for maximum versatility

- Machines available with 4 or 5 axis capability

- Quite a few budget models available that can be adapted to cnc control

- Has a bigger travel in the z axis than a gantry type mill

- Has a smaller X and Y work area than a gantry type mill

- Less ideal for milling wood because of the slower spindle speeds

- Cost is higher than a cnc router

- Requires more skill and knowledge to machine metal parts

I have articles on connecting a cnc machine to a PC and Cnc milling equipment which may be of interest to you, be sure to check ’em out.