In this article I will list and explain in detail where necessary what you need to do to keep your hobby cnc mill or router running at its best.

Keep your cnc mill clean

Always clean your cnc after it has been run. Keeping your machine clean involves brushing off all the chips or dust left on the machine, then using a shop vac if you have one, vacuum up all the junk you just brushed off.

Then wipe down any remaining dirt with a shop cloth or paper towel. Concentrate on sensitive areas such as cables or exposed stepper motors. Make sure to remove any debris or dust from lead screws or any moving parts.

Keeping your machine clean will extend its life and every time you do it you are giving your machine a visual check. This is called preventative maintenance and doing this will help you stop and prevent any problems from developing or getting worse.

Oil the ways and leadscrews

After cleaning you should apply some oil to the lead screws and ways. Doing this will enable your machine to be ready to go when you next need it.

Oil also prevents the steel components of your cnc from developing surface rust. That is why you should do it after running, if you don’t use your machine for a while it will be protected.

I use ordinary ATF oil, the red stuff, for oiling my ways and leadscrews. I apply it from a typical pump oil can, like this one.

[amazon box=”B004F7MZ34″ price=”hide”]

Once you have oiled the leadscrews you can run the table through its full movement in all axes to coat the full length of the leadscrew.

I have written a gcode program to do this task for my machine.

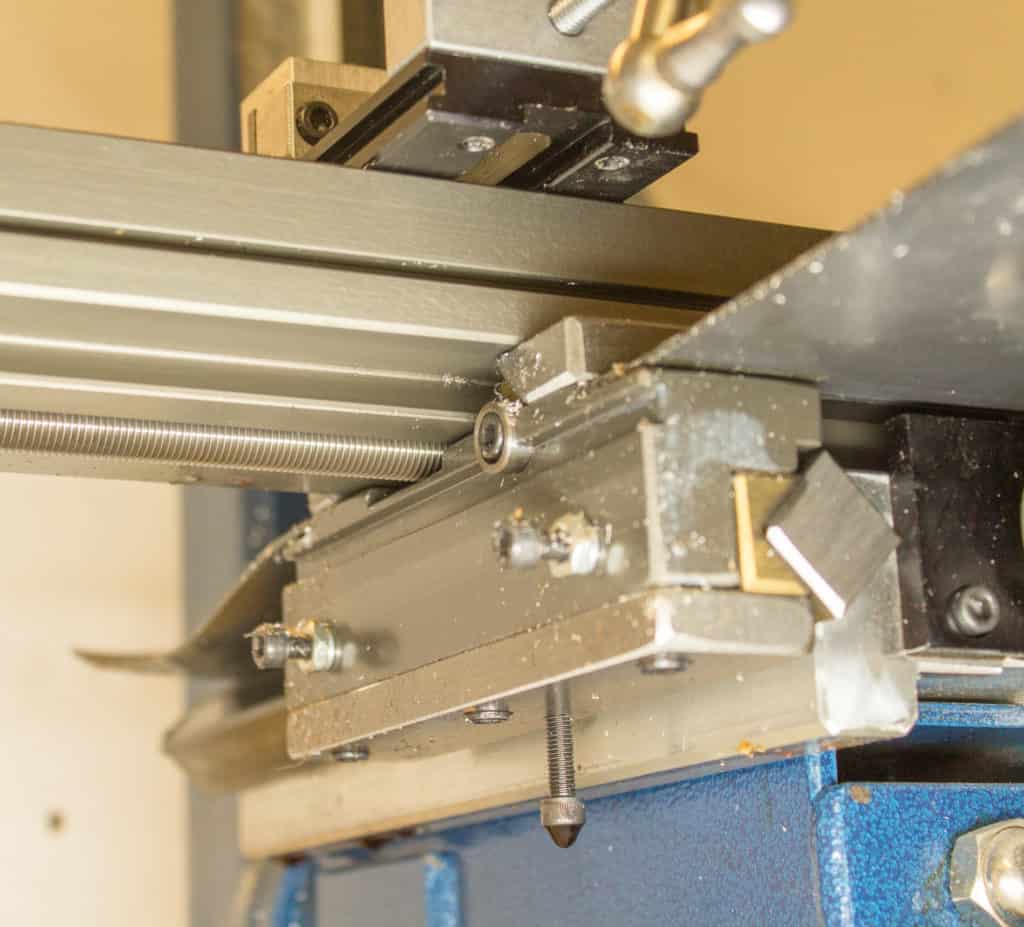

Rubber way covers

A typical cnc desktop mill will benefit from way covers, this will protect the lead screws and ways from the worst of the chips. It will make clean up a lot easier.

They are usually made from a flexible rubber sheet. These are really easy to clean, yay.

Adjust your cnc machine correctly

Depending on the type of machine, you will have to make sure it is running as smoothly as possible. On a typical desktop cnc it will have adjustable slideway gibs. These can be adjusted to reduce the amount of play or “slop” in the table of your machine.

This has to be done carefully because if it is too tight the table will bind and possibly jam. If it is too loose the machine will lose accuracy and possibly vibrate when milling.

A good guide for setting up a taig mill can be seen with this link.

Repair damage to the table surface

If you damage the surface of your table you will need to fix it. If you accidentally plunge an endmill into your table it can kick up a burr. Just clamping parts to the machine can put minor dings in the table.

This type of damage can create an uneven table surface, preventing a part or a vise from sitting flat on the table. This in turn can create inaccuracies and vibration.

This can be fixed with a flat honing stone. Get into a habit of checking the table or bed surface prior to setting up any job and stoning the surface whenever necessary.

Flat honing stones can be found on amazon.

[amazon box=”B0006NDPLW” price=”hide”]

Keep your software updated

Maintaining your software as well as your hardware will keep your machine running at optimum efficiency. Check the relevant websites occasionally to make sure you have the latest version.

The biggest issues with software usually come when windows updates or you add new software that causes a conflict.

The best advice I can give is to use a separate PC for your cnc, preferably not connected to the internet. Once you get your PC running the cnc software properly it shouldn’t change or cause future software conflicts.

If you are using cad/cam software you don’t have to create your programs on the PC that runs your machine, programs can be loaded via a USB drive or similar.

Cnc Equipment maintenance

As well as maintaining your machine you need to maintain your equipment. There are specific items of equipment used with a cnc machine that needs very careful maintenance.

ER collets

If your machine has an ER collet system, or any collet system, you need to keep it clean and clear of any debris.

Small chips collect inside the slits in the collet so using compressed air is necessary to clean them out effectively. The collet nut needs cleaning to ensure the collet seats properly and engages the clip in the nut.

The spindle itself will need cleaning out with a shop cloth, anything left in will cause the tool to run out. Tool runout will affect the machines accuracy and will increase tool wear and noise.

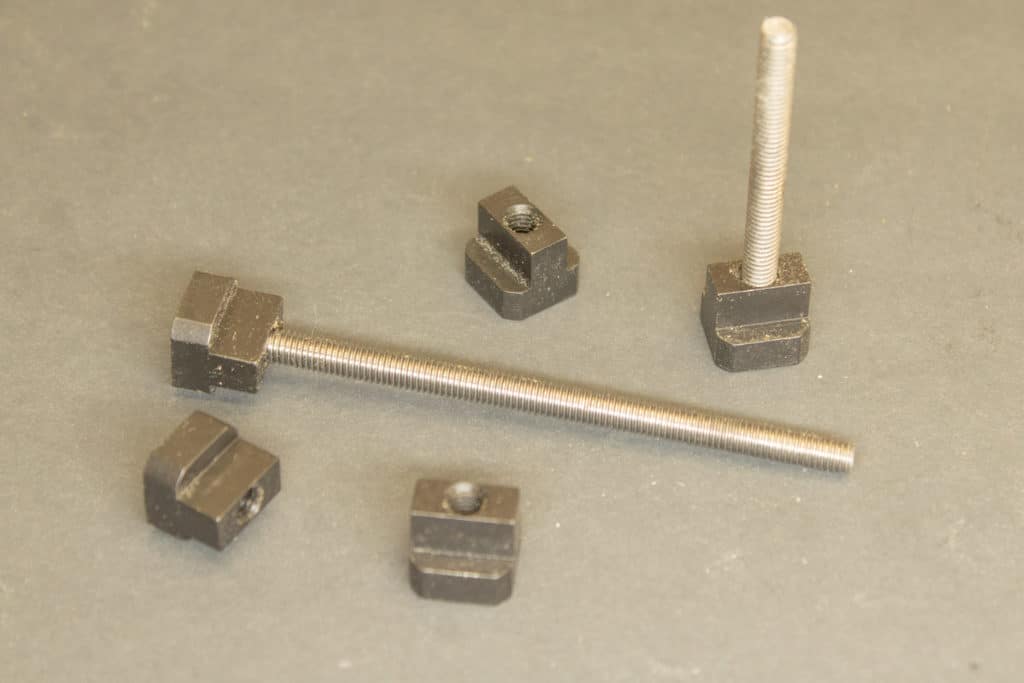

Clamp studs and fixturing

Keeping your clamp studs, clamps and fixturing clean after every use will guarantee they won’t get damaged over time.

Debris and chips on the threads will cause the nuts to seize on the studs which is extremely frustrating.

Any fixture plates you use need to be treated just like they are a table bed. The same rules apply for clamping parts to a fixture table, keep it clean and smooth. (no dings or burrs).

If you own a fixture plate with lots of threaded holes for clamp studs, you can add set screws to the holes you are not using so they don’t fill up with crap.

This will protect the threads and make the fixture plate easier to clean.

Be organised

This is an easy one, but something too few machinists do. It’s pretty simple to organise everything. Just make some racks for your collets and have a place for everything that gets used regularly.

Keep your workshop floor clear of any obstacles, have a spot for everything to be out of the way.

Making a simple rack for your collets would be a perfect opportunity to practice your machining skills. All you would have to do is drill or interpolate some holes in a strip of material. You could just use some wood for a rack.

Working safely

Keeping your workspace clean and organised involves having a routine before and after you run your machine. Create a simple checklist that works for you and it will decrease the likelihood of an injury accident.