I’m going to give you a quick rundown on what equipment you will need to get started with a benchtop cnc milling machine in your workshop.

What equipment will you need to operate benchtop cnc mill?

There is going to be a bare minimum of equipment that you will need to run your cnc machine. Some of these are going to be dependant on what type of machine you have or want…

A workshop or room

The first most essential part will be a room or workshop.

You don’t want to put your machine in your bedroom.

I use a room in the basement, this is ideal for keeping the noise away from the rest of the house.

Small machines are not very loud, but it could get old quickly for anyone else in the house if they can hear it running.

A bench

Once you have your room, a sturdy bench will be necessary for all but the smallest cnc engraving machine.

A desktop cnc mill like a taig will need bolting to the bench to keep it from moving about.

This is certainly a safety issue, so make sure your machine is secured properly.

Windows PC

You will need a computer to run your machine. It can be done with a laptop, but ideally you will want a desktop computer.

You will not need an expensive PC, most people have an old desktop they are not using. You can pick up a cheap second hand machine from local classified ads if you don’t have one.

Don’t bother trying with an apple computer. I’m sure it can be done, but just don’t..

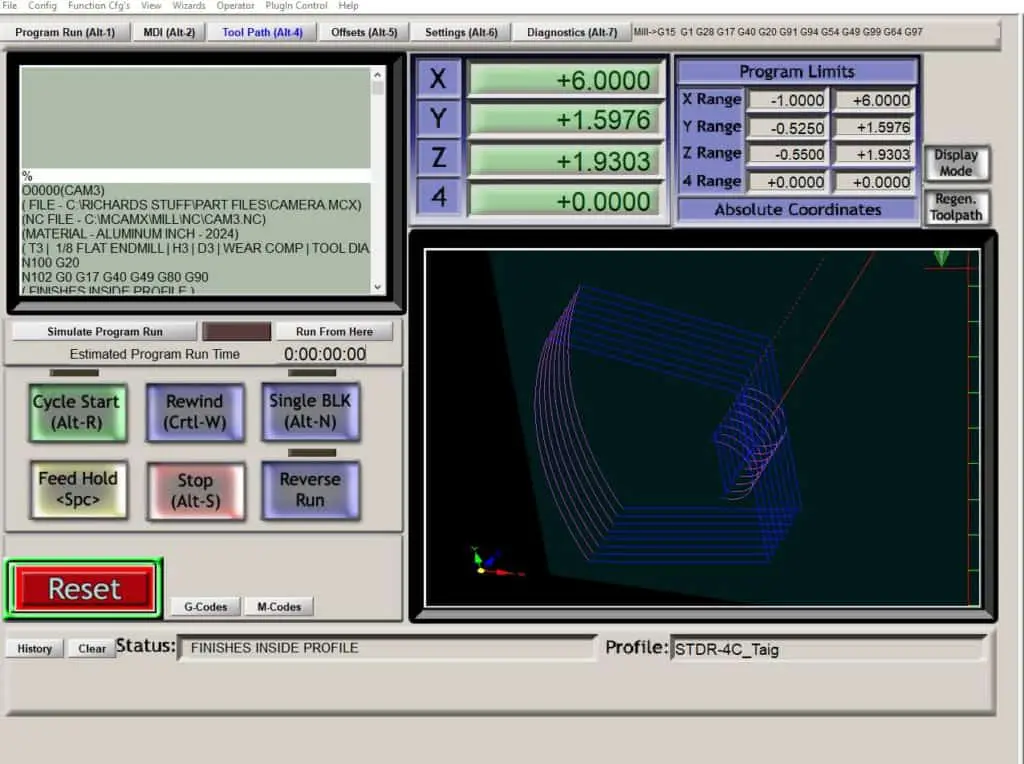

Cnc control software

Once you have your PC you will need software on it to control your machine. Popular choices are Mach3 or universal gcode sender.

I wrote a post about connecting a cnc machine to a computer, you can read it through this link.

G-Code Visualizer

Writing your own G-Code programs can be tricky, being able to check them visually before running them on your machine is recommended.

You can do this using G-Code visualizer software. Although not essential, there are free ones available, so they are worth mentioning.

Check out my ‘G Code simulator‘ article.

An endmill or engraving tool

This one is pretty obvious. If your machine didn’t come with an endmill you will have to get one.

The cheapest one you can find will do if you are a noob and need to practice.

I would suggest getting the largest size dia that your machine will take. The bigger the diameter, the less likely they are to break if you abuse it.

You can get a set of endmills from Amazon like these, they certainly won’t break the bank.

[amazon box=”B08BLM84K6″ price=”hide”]

Something to test your programs on

One trick I do occasionally is to do a test run on a piece of throw away material, such as wood or insulation foam.

It will help me prove out a program and see if it might cause any problems when it gets run in aluminum or steel.

Insulation foam only needs some double sided tape to keep it in place while you practice.

If you do mill wood or foam, use a shop vac to suck up the dust while it runs, don’t breathe it in…

Safety glasses

Speaking of safety, getting some glasses and wearing them will stop you from losing your eyesight. They are super cheap.

I have had metal in my eye more than a few times, it’s not fun. Don’t try it.

[amazon box=”B01AWK1XAS” price=”hide”]

Recommended equipment needed for your cnc machine

After you have the basics and have got your machine running, there is a ton of other equipment you could invest in. A lot of choices will depend on the type of machine you have and what you want to make with it.

I will list what I think is recommended based mainly on machining metal projects. There will be some equipment that will be usable for any type of machine and some that will be specific for metalwork.

Fixturing, vise, clamps etc

This is a big one. Not having anything to hold your projects will stop you before you even get started.

A vise suited to the size of your machine is essential. I have two, this helps if your part is quite long, both ends of the part can be clamped in each vise.

The other fixturing essential are clamps, threaded studs and t-slot nuts. These are the standard for clamping larger parts to the table.

They can be used to clamp custom made fixture plates to the table for holding many smaller parts.

[amazon box=”B08C26KVD3″ price=”hide”]

MPG Pendant

I consider an MPG Pendant is an essential accessory. The machines I use at work always have an MPG, (manual pulse generator).

As soon as you use one you will wonder how you managed before.

They make manually jogging your machine to set your datums a breeze. You will have more control over your machine making it less likely to crash when setting up your machine.

The tactile feel you have when using it beats pressing soft keys with your mouse any day.

A newer version of the Vista cnc pendant that I own and recommend is available on Amazon.

[amazon box=”B00R4D9IA4″ price=”hide”]

You can check out my full review of the Vistacnc pendant shown below.

Endmills and drills

A larger selection of endmills of various sizes will be needed if you want to machine more complex parts.

Ball endmills are essential if you want to do surface machining of 3D forms and angles.

A drill index in both imperial and metric will be almost a necessity so you never get stuck trying to make a part.

[amazon box=”B07JDWDVP4″ price=”hide”]

Holes can be machined on a mill but drilling is quicker and can go a lot deeper than using an endmill. A center drill will also be needed if you are using drill bits.

Air compressor

A source of compressed air is extremely useful, keeping your parts clear of chips will help prevent cutters from breaking.

A big compressor is not necessary, a small d.i.y. unit is all you will need.

[amazon box=”B08F7H1M55″ price=”hide”]

The big issue with these budget compressors is the noise they produce. It can be really bad in a small room and definitely a no go in a house.

I avoid this problem by using an old fridge compressor retrofitted to the tank of a “donor” compressor.

It buzzes like a fridge.

Edge finder

To accurately find the edge of a part to set your datum you will need some type of edge finder or wobbler.

There are various types available from the classic wobbler to an electronic edge finder that lights up when it touches the edge.

Here is an article dedicated to edge finders, it explains how they are used and which type is recommended for use on a hobby machine.

[amazon table=”3515″]

Measuring Equipment

If you want to make accurate components for your hobby that may even be part of an assembly you will need measuring tools.

This will include dial or digital calipers, micrometers, gauges of all types and even a steel rule will be essential.

[amazon table=”3408″]

Here is an article dedicated to micrometers, explaining which ones are recommended for use in a home workshop.

Dial test indicator

These are important whatever type of machine you own.

I have one permanently attached to my manual micro lathe. I use it with an extra long tip for the Z axis. It’s basically a poor man’s readout.

The main use is to check for flatness or angle. It can also be used to measure depths and distances.

I find that a smaller finger dial is more useful for a small desktop cnc.

They are more compact and can be mounted in the machine spindle. This enables it to be used for setting datums to the center of a part by “sweeping” against an edge or diameter.

I have an article explaining the uses of different dial indicators and recommending the dials I use.

[amazon table=”3433″]

1-2-3 Blocks

These are precision ground steel blocks. They measure 3” by 2” by 1”.

They are very useful, you can check the price on Amazon here.

[amazon table=”3484″]

I couldn’t possibly list everything they can be used for but here are a few.

- As a square

- As a fixture block or a stop

- Check the calibration of micrometers

- Set the height offset of tools

I have written a full article on 1-2-3 blocks, click the link to read it.

ER collet sets

Having a spindle that takes ER collets makes your machine very versatile when it comes to tool choices for your machine.

Having a full set of imperial and metric collets will ensure you are very rarely limited to the size of drills and cutters you can use.

I have found that using a drill chuck in your mill takes up way too much space. Having a good choice of ER collets eliminates this problem.

You can read my article on ER Collets if you need to know more.

These can be found on Amazon.

[amazon table=”3469″]

ER Collet racks are also available, or you can make your own with G Code available in the Cnc Philosophy store.

Parallel set

If you have a vise for your machine you will need some parallels.

These will lift your part above the vise jaws while keeping them level to the table.

A small cnc machine vice will only need a couple of small pairs of parallels but they are only available in sets.

[amazon table=”3493″]

I have written a full article about parallels, you can read it here. .

Soft blow hammer

These hammers or mallets have heads on them made of plastic or leather.

They are designed to avoid leaving dents or marks on the face you are hitting.

They are most useful for making sure a part is sat down firmly on a pair of parallels in the vise.

[amazon box=”B00MWVAUUA” price=”hide”]

Small shop vac

Once you have made a mess you need to clean it up.

Using a small shop vac has to be the easiest and most efficient way of doing this.

One of those purchases that will always get used.

[amazon box=”B07QG3X6KQ” price=”hide”]

Selection of hand tools

A set of small hand files and a hole deburring tool are just a few of the hand tools you should consider owning. I just collect them as they are needed.

Tap and die sets

I’ll let you into a big secret. The tap and die sets you can buy from the big box stores or Amazon are shit.

They can be useful, mainly for repairing or cleaning out rusty or damaged threads. So if that is something you need to do then these sets certainly have value.

The difference between tapping a hole with a cheap tap and a good quality tap is like night and day.

I would recommend buying individual good quality taps from an industrial supplier such as mcmaster carr. If they are available, choose HSS taps, (high speed steel), then it should last you a few hundred holes.

Micro lathe

I know this might seem extreme for an accessory for your mill, but as you start doing more projects you will discover that they are pretty much a necessity.

[amazon box=”B001R23S9U” price=”hide”]

I own the Taig micro lathe and I probably use it more than my mill. It really comes in handy for quick fix it jobs.

I used it to make an arbor for a slitting saw, fixturing parts and prepping round stock for my A axis on my cnc mill.

Then, once you own a lathe, you will need accessories for it…. 🙂